New sensor to measure materials with microwaves, reported in Nature

“Microstrip sensor and methodology for the determination of complex anisotropic permittivity using perturbation techniques” is the title of the research article by MC Héctor Morales Lovera, doctoral student in Electronics, and Dr. José Luis Olvera Cervantes, researcher at the Electronics Coordination of the INAOE, which was published a few days ago in Nature.

Héctor Morales obtained a bachelor's degree at the Comalcalco Higher Technological Institute, and a master's degree in Electronics at the INAOE under the guidance of Dr. José Luis Olvera. He is currently doing his doctoral thesis with this researcher. Asked why he dedicated himself to Electronics, he comments: “Since I was little I was one of those curious children who loved to experiment with their toys, take them apart, it was that curiosity that made me love Electronics”.

About the research project reported in Nature, MC Héctor Morales explains that 5G technology is expected to improve data transfer speed and foster an environment where everyone and everything is connected (Internet of Things, IoT), both users such as everyday objects, allowing their management and identification by other devices, just like the human being does.

This requires that the circuits and communication channels be designed with greater demands in terms of speed of operation, bandwidth, energy consumption. However, with “the increase in the speed of operation of telecommunications systems, the effects caused by the characteristics of the materials with which they are manufactured begin to be more and more evident. For this reason, an improvement in the models and methods for characterizing materials in the microwave range is required”.

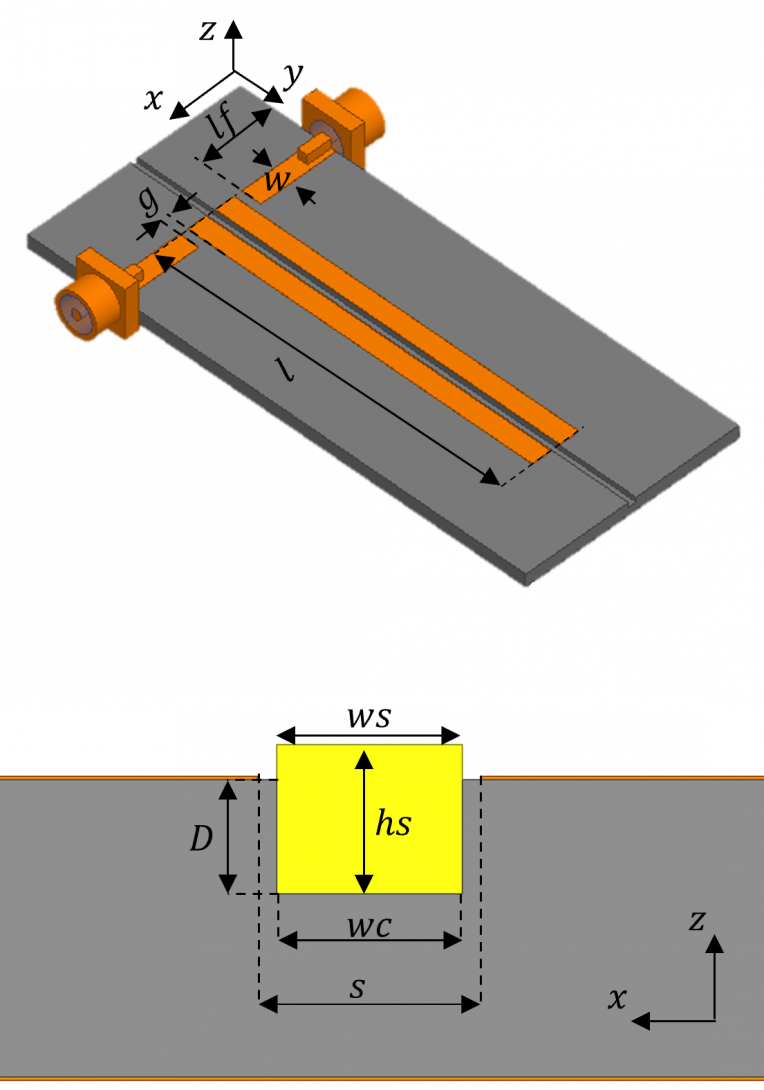

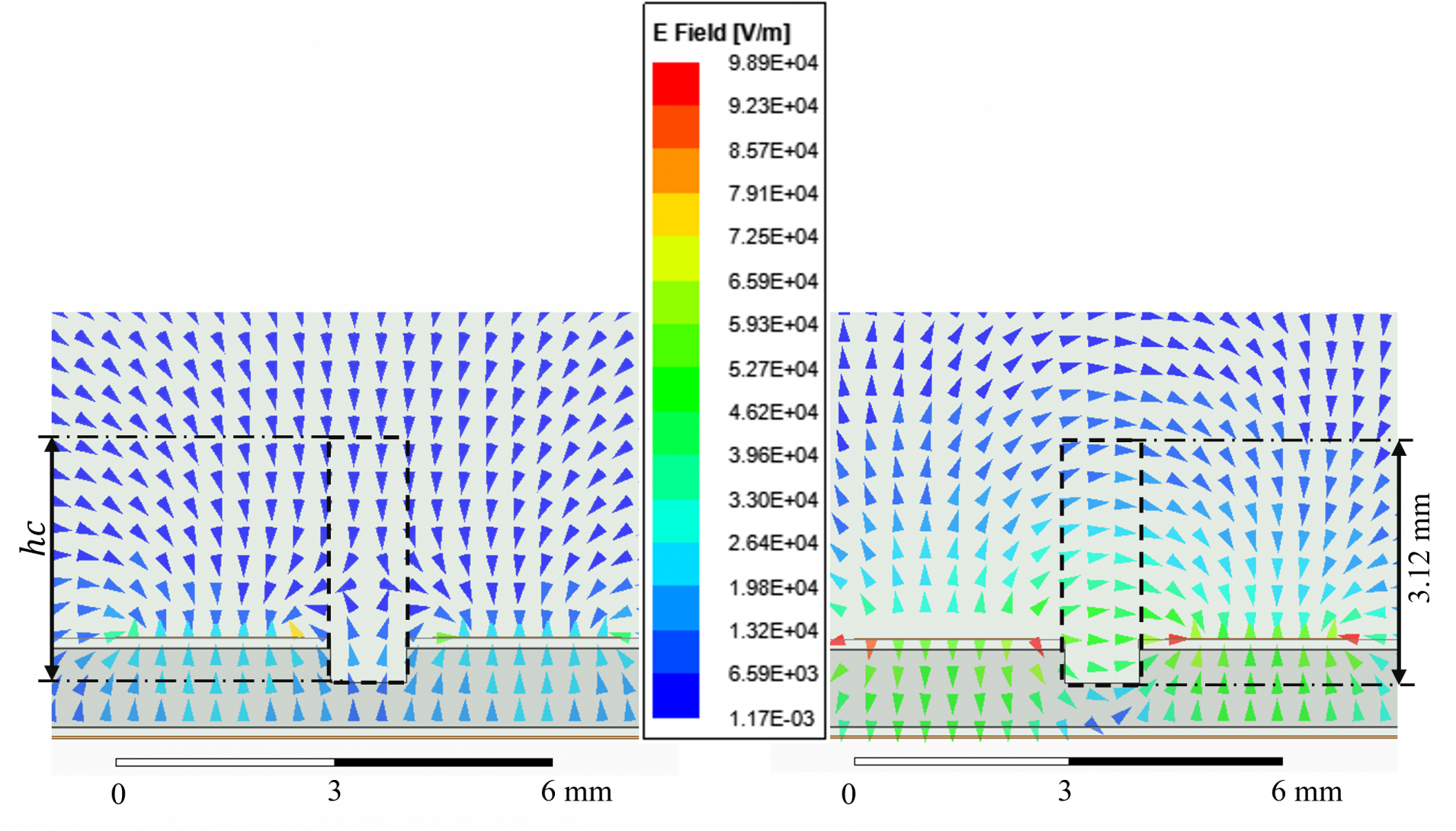

“In this work, a sensor and methodology for the measurement of the uniaxial dielectric constant of anisotropic dielectric materials using microwaves are presented. That is, the dielectric constant is measured in the vertical direction and in the horizontal direction in a material. When the material presents different dielectric constants in the evaluated directions, it is considered anisotropic. In the opposite case (the answer is the same in any direction) the material is known as isotropic. The information obtained with this method will allow RF and microwave engineers to increase the reliability of their designs, since more information is obtained from a material compared to conventional methods. The sensor is based on microstrip resonators, enabling non-destructive and non-invasive testing of Samples Under Test (SUT). The method is low-cost and fast, since with a single sensor it is possible to characterize many samples. Also, because the methodology is measurement-based (does not require numerical analysis), it makes it easy for designers to measure the permittivity of the dielectrics from which circuits operating in the microwave range are made; PC motherboards, cell phones, antennas, communication channels and all the elements that make up 5G networks for the IoT”, he explains.

Microstrip, he adds, is a technology that consists of a kind of sandwich: the upper layer is a trace where a signal goes on a conductive layer, below that conductive layer there is a dielectric substrate and the lower layer is another conductive plane that is used as a reference or ground plane. It is important to note that the electrical characteristics of transmission lines, including microstrip, depend largely on the dielectric substrate where it is implemented. Since this determines the electrical length, phase and dispersion of the transmission lines.

“This work reports a sensor based on coupled resonators, which accepts a sample under test (SUT), which is placed through a slot that is integrated into the substrate. The slot delimits both the size and the position of the SUT, and this makes the proposal compatible with resonance perturbation techniques. Perturbation techniques are widely used in the field, but with other technologies operating at frequencies above 10 GHz, this implies greater measurement uncertainty and higher costs. This work provides the user with much of the analysis required by the anisotropic characterization, since what is conventionally done is very time-consuming, due to the fact that an exhaustive electromagnetic analysis of the sensor and the SUT is required. This work comes to simplify all that, since it eliminates the exhaustive calculation by means of measurements of standard materials”.

Héctor Morales Lovera indicates that the sensor is not limited to measuring solids, since it can measure liquids, powders, gases, but it focused on the anisotropic analysis of materials.

“Analyzing anisotropy is very important at an industrial level, in the area of ??high-frequency electronics, for example, the reliability of the designs carried out by microwave engineers depends on the amount of information available on the dielectric substrate, the which are mostly anisotropic. However, designers usually choose to consider substrates as isotropic (knowing their anisotropy) due to the complexity of the analysis that is needed to know the behavior of the material in different directions”.

To conclude, he mentions that this article is part of his doctoral thesis project, which is about the characterization of 3D printed dielectric substrates for applications in the microwave range. “The characterization is also with an anisotropic approach. In addition, in the thesis I am working with applications of these 3D printed substrates, that is, I am developing the design of different microwave circuits. In this case, the sensor was one of those circuits that I designed.”

Luis Enrique Erro # 1, Tonantzintla, Puebla, México, Código Postal 72840, Tel: (222) 266.31.00, difusion@inaoep.mx

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 2.5 Mexico License.